About Piezography 3-inkjet Direct to Plate Photogravure

Instead of the traditional film positives and exposing screens made of dot patterns, we invented a system using 3 shades of Piezography UV absorbing inkjet-ink & Piezography software that print the positive image directly to the surface of a special photopolymer plate at a resolution of 2880 dots per inch that can then be exposed directly to UV light. These 3 multi-overlapping, inkjet-inks produce tens of thousands of more gray levels than can film and dot.

These gray levels are successively less & less opaque to UltraViolet light and the slow to expose Green Mountain Plate becomes successively more & more resistant to being hardened. That's a beautiful marriage of inks and substrate that once processed produce a plate with an unusually long and smooth tonal range for photogravure and results in prints that rival the smoothness of platinum printing.

Most of the inkjet-ink droplets are microscopic in size and too closely packed to be visible by the human eye. Because of the absence of film and glass, the exposure to Ultraviolet light causes these tiny grains of ink to form perfect undiffused divots of varying depth in the surface of the plate that when inked, wiped, and printed on an etching press cannot be seen in the print even with the strongest loupe. You can think of it as a microscopic aquatint.

Piezography has been known for over 30 years to be the one medium that can print 265 distinct gray steps between dMin (paper white) and dMax (maximum black). Piezography first “linearizes” a medium to optimally print with a wider tonal range and then “calibrates” it so that the resultant prints match images on both calibrated displays or non-calibrated displays. There are two methodologies we can employ according to the technical capabilities of our customers so that the photogravure prints that the plates produce meet our customer’s expectations.

This same process that we employ in our studio is the same process that we teach those who attend our Direct to Plate workshops or can even be easily ordered for your studio from our online shop. Of course you can also contact us to begin a collaboration.

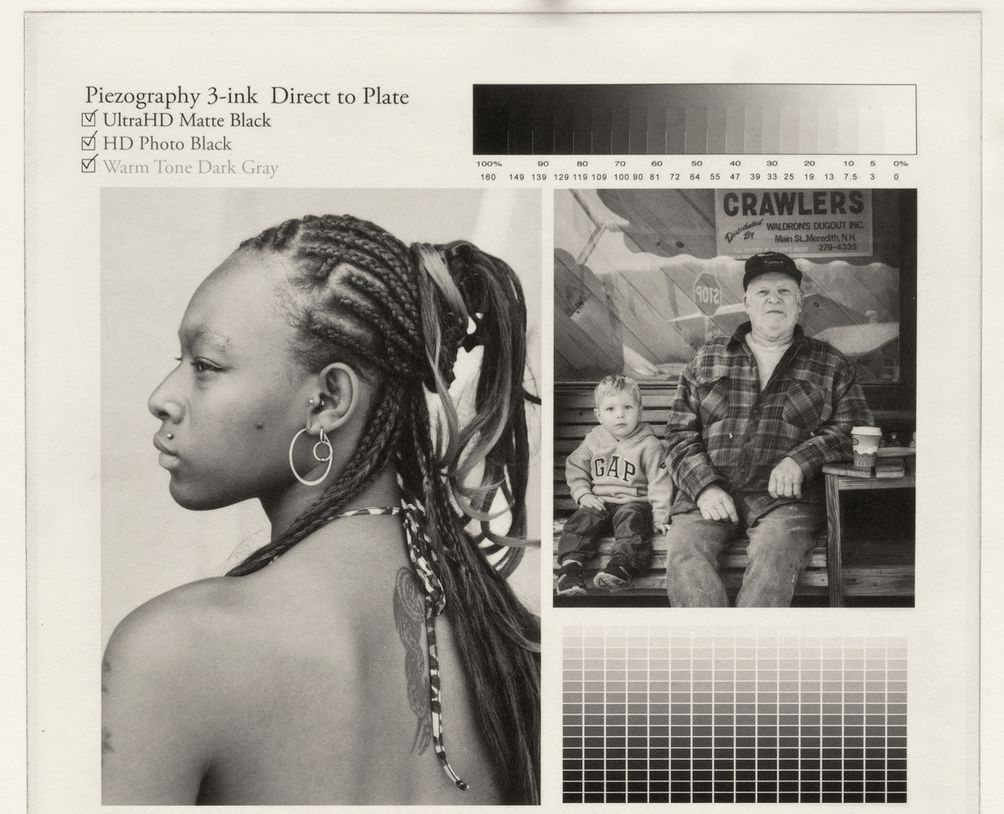

We illustrate below how this is achieved:

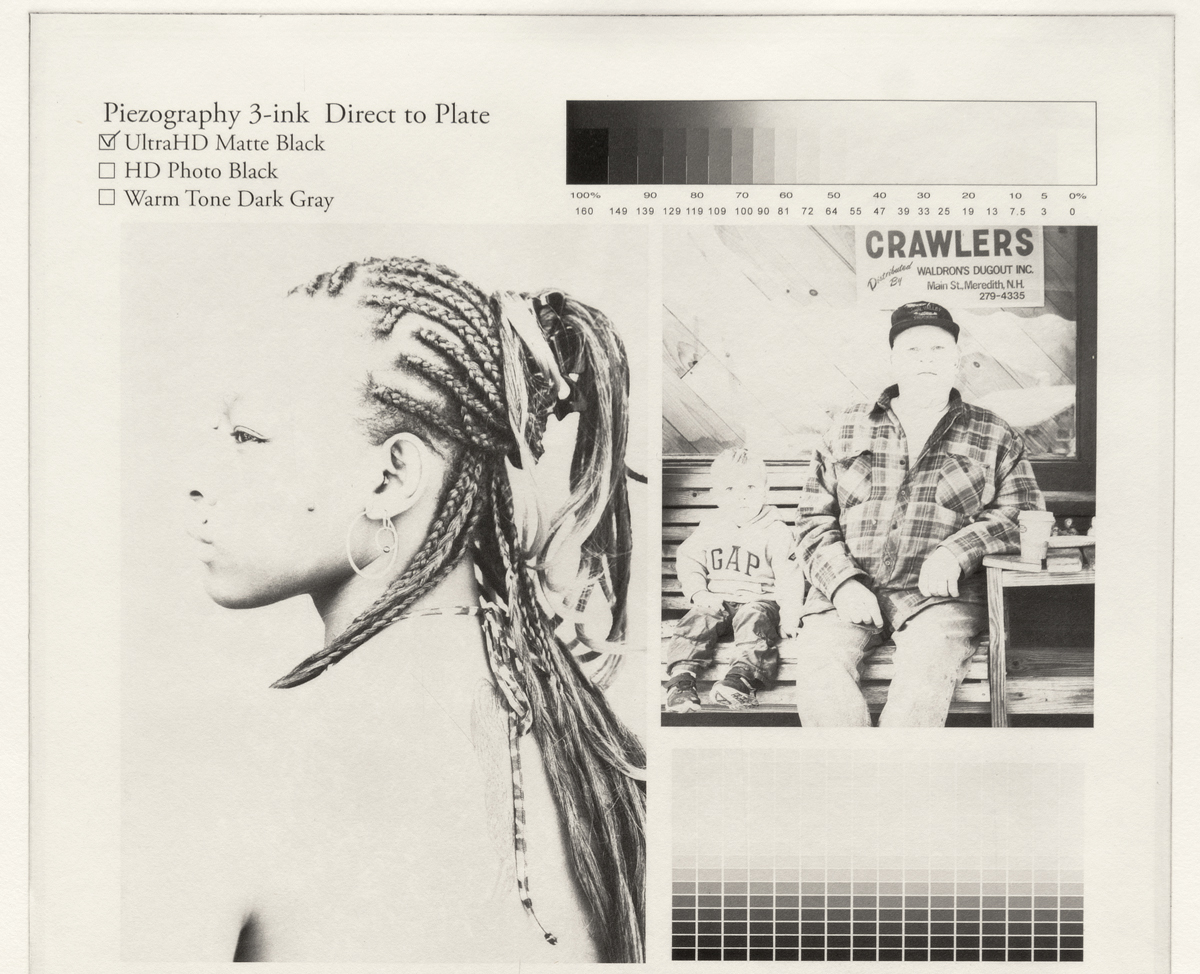

Piezography inkjet ink #1: UV opaque

To illustrate how we do this we isolated only the most opaque inkjet ink using an independent channel printing software and inkjet printed the Green Mountain plate with only the most opaque of the 3 inkjet inks. The other two inks were turned off. We exposed and processed the plate. Then we hand inked, wiped and printed the plate with an etching press using Copperplate Warm White paper to show as an example what only the most opaque inkjet ink is responsible for when using the 3-ink Direct to Plate process. The opaque inkjet ink (inkjet ink #1) produces only the shadow range but does so without introducing dots that perceptible to human

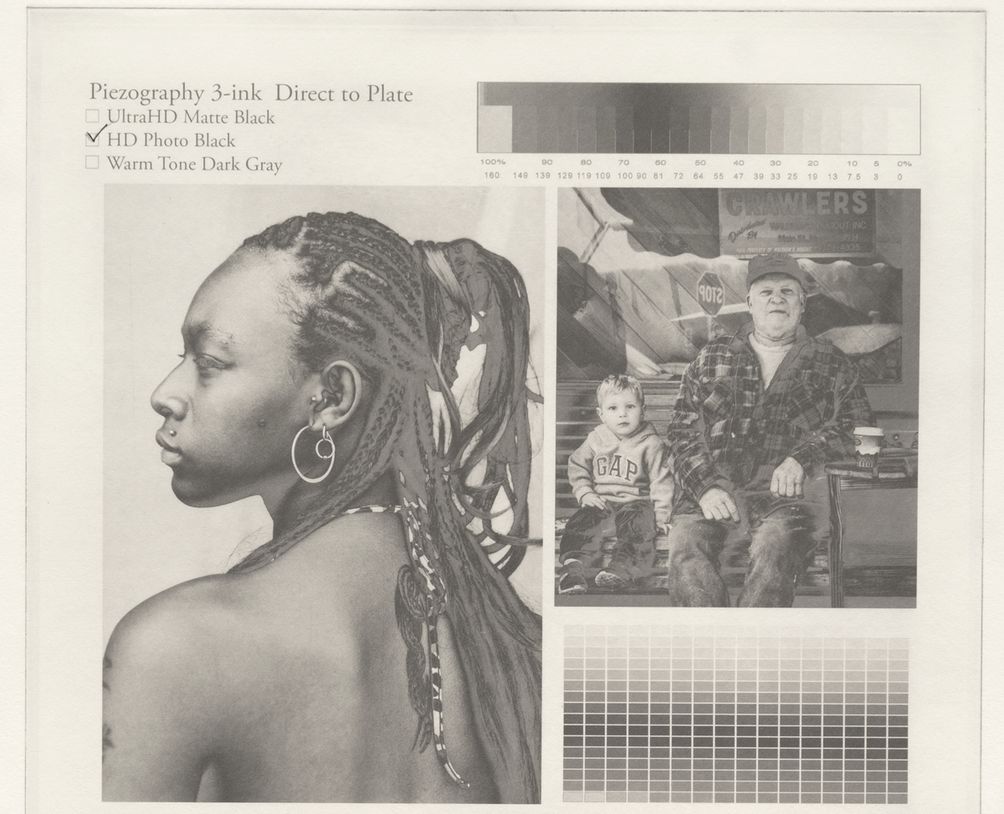

Piezography inkjet ink #2: UV near opaque

Then in the same way we isolated only the nearly opaque inkjet ink and inkjet printed another Green Mountain plate, exposed and processed it. Then we hand inked, wiped and printed the plate to show you only what the nearly opaque inkjet ink is responsible for. The nearly opaque inkjet ink (inkjet ink #2) produces the mid-tones without compromise. You can see that it underlaps the shadows which will further smooth out and eliminating the visibility of those dots. The same carbon etching black ink used to print the first plate is used again to print this plate. The reason it is not as black as the first print is because the dots produced by inkjet ink #2 were not as opaque as inkjet ink #1 and therefore produced much shallower dots in the plate that much less etching ink can be pushed into.

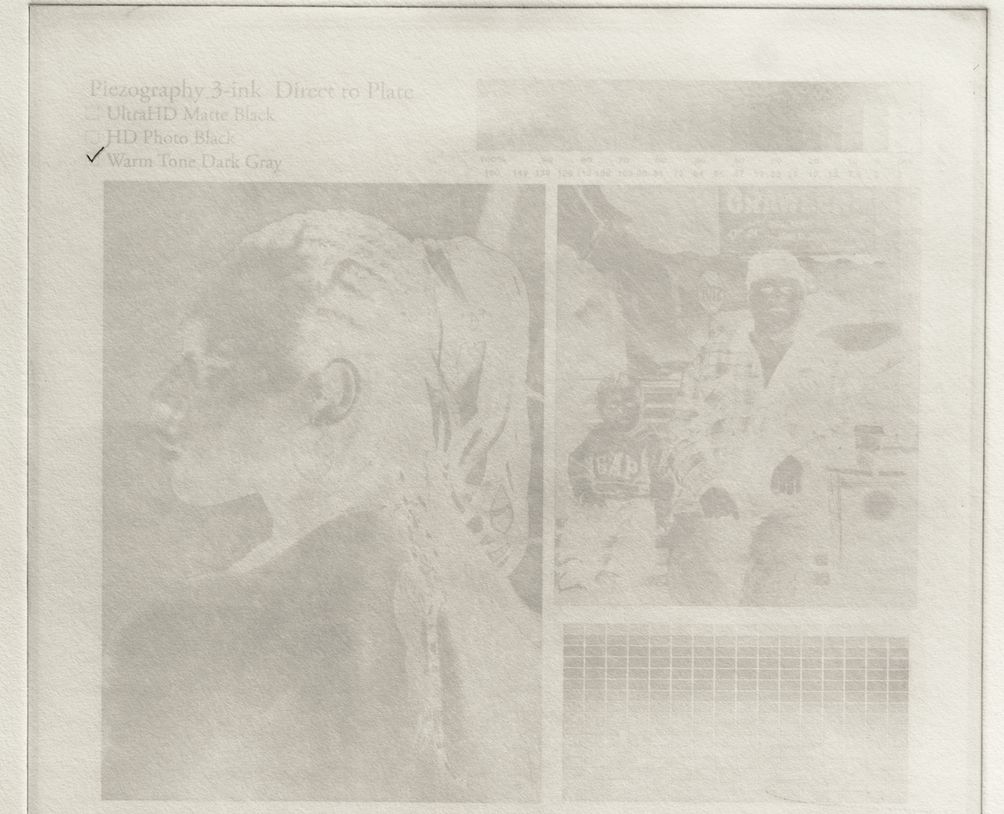

Piezography inkjet ink #3: UV semi-transparent

Finally, we isolated only the transparent inkjet ink and inkjet printed another Green Mountain plate, exposed and processed it. Then we hand inked, wiped and printed the plate to show you only what the transparent inkjet ink is responsible for. The transparent inkjet ink (inkjet ink #3) produces the highlights without compromise. You can see that it underlaps the mid-tones which will further smooth out and eliminate the visibility of those dots. Your eyes would not be able to discern these highlight dots because we have printed them so tightly close together and the value of gray is too light to see. Were they not printed this way we would need lots of dark dots spaced far apart to assimilate such a light tone. Inkjet ink #3 is so transparent, and yet Green Mountain Plate is so sensitive, that during the exposure - the same exposure time is used for all three of these tests... the divots formed are so shallow that the same strength of carbon black etching ink used in the previous tests prints prints as light as you see in the print

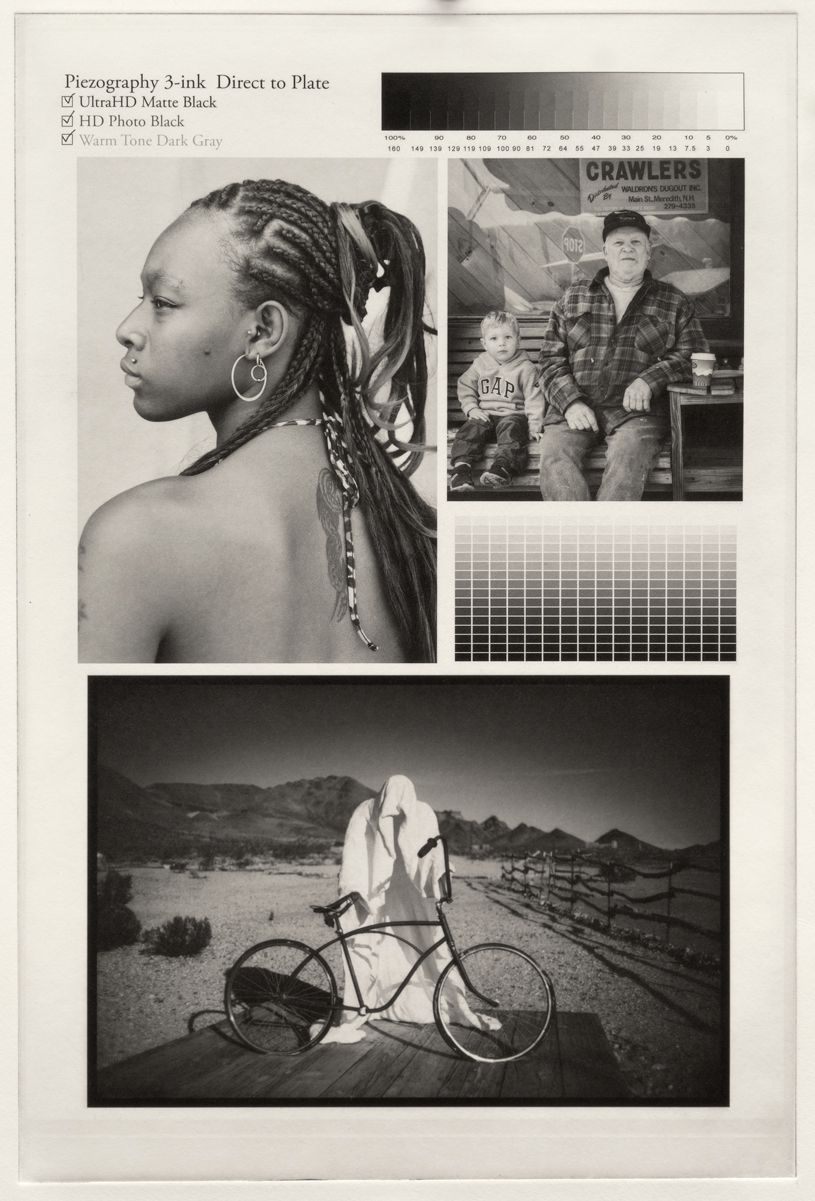

Piezography inkjet inks #1, #2, and #3

In this example, we printed a fourth plate but this time using all 3 of the inkjet inks together in the normal way that we use and teach. This is a calibrated process which explains why our tonal scales are so perfect. The end results are dotless, smooth, high in acuity, and easily separate 256 gray values.

We are the only studio in the world that formulates its own inkjet inks. We produce a system of inkjet inks and software called Piezography. We were the first studio on Earth to begin computer printmaking in 1984 and we have been known since 1995 for printing the highest standards in black&white prints, negatives, and photogravure plates. We also formulate our own color pigment inks.

Further to our high fidelity output is our ability to calibrate any alternative process to produce prints that match your display whether it is a calibrated display or one that is uncalibrated. In this example we have done it with photogravure as easily as we would with platinum printing or regular inkjet printing.

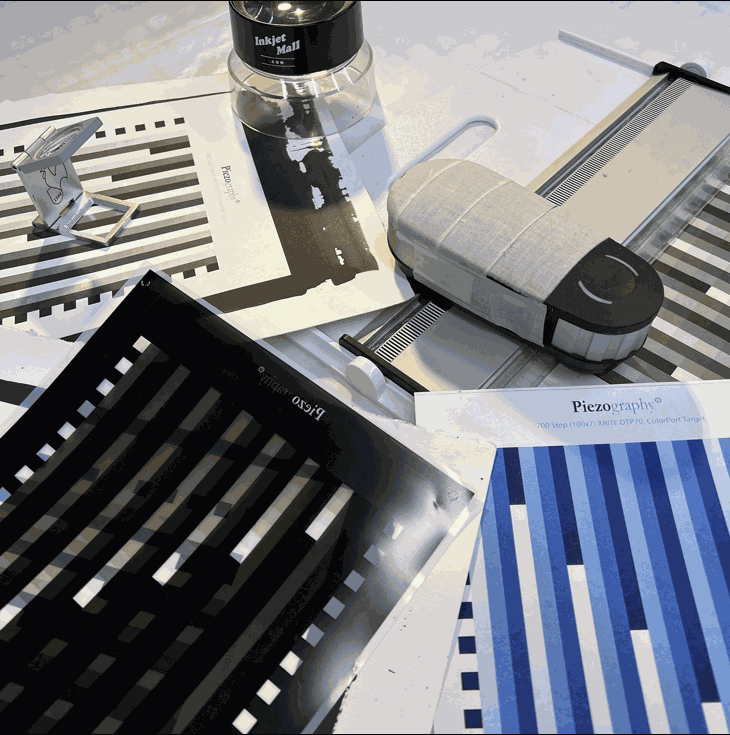

Here is a short overview of the Direct to Plate process

First things first. We have converted our EPSON large format printers with the Piezography Professional gradated carbon inkjet ink set. No more color inks! We formulate our own inks with special grades of carbon. Our printers use a total of 11 inks. Although we produce 11 shades of Piezography inks, we use the nine shaded Piezography Pro ink set in an 11 ink printer. We include an additional HD Photo Black and an additional Ultra HD Matte Black in our orange and green ink slots which would otherwise be used for the very lightest shades of Piezography ink. The HD Photo Black in one of the color positions can therefore be used at the same time as our UltraHD Matte Black ink. Ultra HD is the darkest and most opaque black ink available on Earth. Both Ultra HD Matte Black and HD Photo Black are critical for the 3-ink process. We occassionaly use the second UltraHD Matte Black for experimental reasons when it is desirable to have two times the world's most darkest matte black ink printing.

This particular ink set layout can be used for making calibrated digital negatives or positives. It can also be used to make standard Piezography prints on paper.

Did you know that if you can find a Piezography supported printer model with just 3 working ink channels you can install the 3 necessary shades of Piezography Pro inks and adopt our process in your studio? Crazy, right? You can probably find a professional printer with a compromised printhead for free. Read more about that here.

The Green Mountain Plate

This is pretty special photopolymer plate and its required for our process. It is both the most sensitive and the slowest exposing plate available. That it happens to be .95 in thickness is a nice benefit as it is thicker than most plates. We stock this plate up to 31 x 42 inches. Green Mountain Plate does not have any of the dreaded issues such as spots and measles and striations and striping of other grades of photopolymer being sold today. It is a super premium product and its sensitivity and slow exposure allows us to expose transparent inkjet dots as easily as fully opaque inkjet dots. Most studios have trouble printing dots of ink opaque enough to make a Direct to Plate. The Green Mountain Plate allows the use of nearly any type of inkjet ink. But, Piezography inks are made from carbon and are naturally UV absorbing and sharp printing. We print at 2880dpi using Piezography software. We also provide this software to folks who come to our direct to plate workshops. We offer a turnkey package to make things super easy in your own studio.

Piezography Photogravure Software

This is a system of software we write ourselves that organizes how a continuous tone image is printed onto the Green Mountain Plate. It provides several important functions. First, we cannot use the EPSON printer software that expects color inks. Instead, we use an independent ink channel printer driver that allows us to linearize each individual ink channel and calibrate the combination of channels to optimize the amount of inkjet ink being printed and how it is printed in combination with each of the other three inkjet inks. It also serves as a calibration software much in the way that OEM software like X-Rite, DataColor and Calibrite function. Ours works differently because there is no color. We still make spectrophotometric Lab measurement that the software uses to produce printer driver profiles and a special class of ICC profile. These are used for printing and also for previewing. Our software produces photogravure prints that match calibrated displays and also non-calibrated displays using one of two methods. The software we produce can be used for three-ink direct to plate, digital negatives for any alternative process, and for making Piezography prints. We also offer a turnkey package you can use without having to operate special software or purchasing an expensive spectrophotometer

Exposing the plate with UV

We build our own 365nM UV exposure systems and call them the verifiedUV systems. We even designed our own flexible PCB strips using a special class of industrial strength LED chips. They are the strongest in the world. All of our systems are calibrated to one another so that exposures for our various media are all the same from one system to another using UNITS (rather than time). These are the fastest exposure units on Earth and we have been building them for other studios as well. Many universities that have to renew their facilities turn to us for custom builds. Green Mountain Plate can be exposed with other brands of 365nM UV exposure systems. We mentioned that the plate is very slow to expose. In comparison to other plates it can take up to 7 times longer to expose a Green Mountain plate. Therefore, speed for us is of the essence. Yet we first introduced our industrial LED to reduce platinum print exposures to 60 seconds. Because it is a direct to plate process no film is used and vacuum is unnecessary. We throw a sheet of neoprene rubber over our glass vacuum table to prevent it from being scratched. We also build systems especially for home use for plate exposure and for use with contact frames that do not contain the more expensive vacuum option.

Plate processing

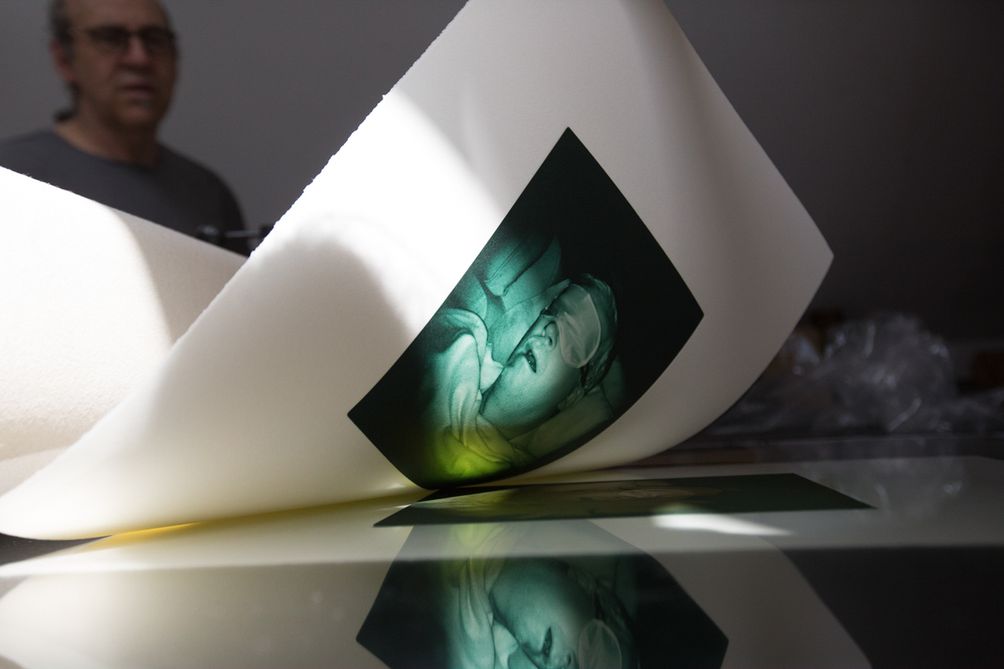

Nothing could be easier. The photopolymer is nontoxic and requires only room temperature water for about 2-3 minutes. We use a soft pad to help remove any stubborn unexposed polymer. The plate is then drained and dried by blotting it with simple newsprint. The Green Mountain Plate does not need to be baked to attempt to harden the underlying structure to prevent printing issues. Green Mountain Plate photopolymer is consistent from the surface to the steel backing. Re-exposure in one of our verifiedUV exposure units is enough to both cure the polymer and "bake" out any remaining moisture. On verifiedUV systems exposure takes from 2-3 minutes. Plate processing and drying is 5 minutes. Curing in a verifiedUV system takes 8-12 minutes. Then with a little trimming if necessary, the finished plate is ready for the etching press. If you come to Cone Editions to collaborate with us you will discover that it takes less than an hour from ok'ing your image on our calibrated display to seeing your first photogravure print from that plate being pulled. And you may be pulling the second one yourself even if your experience in photogravure is super limited.

Inking the plate and printing on press

There really is not that much difference in printing our plates than there is with traditional copper plates, but then there is. What is the same is that the same inks can be used. We happen to prefer oil based etching inks. Many of our workshop attendees prefer to use water based etching inks in their own studios. But, unlike copperplate photogravure, tarlatan should never be used to wipe the excess ink from the plate. Tarlatan will actually remove too much ink to make a good print. Instead polyester wiping cloth is used. We like to finish with tissue. Hand wiping with the palm is not as effective with polymer as it is with copperplate. Green Mountain Plates are actually very easy to wipe. We can prints hundreds of impressions from a single Green Mountain Plate. Naturally, what seems easy and routine for us can be complex in your own studio. Our direct to plate workshops are now our most popular workshops and can provide you with many benefits. We'll make it quite easy for you to print at our standard.

There are several ways to work with us.

We print your editions

You either come here and work in collaboration with us taking advantage of our $450 a day rate and a 40% discount on all our printing services... or you send us your images and we can proof and print your editions working together via yours and our monitor, zoom, and UPS to deliver proofs and prints. When we work remotely our prices are reflected in our pricelist.

Contact us to start a project!

We make photogravure plates for you

You send us your images and we produce them into ready to print photogravure plates for your own studio. You can work with us directly at our published rates or use our online shop to save a little money and take advantage of Shopify low ship rates to anywhere around the globe.

You come and take a workshop with us

You don't have to be interested in bringing our process to your own studio to come and take a workshop. We have tons of folks who come to take the workshop just to make lovely prints of their images in our unique process. And if you do come to take a workshop to bring it back to yours...we've made that much easier beginning in 2024 with a turnkey package. You can also book a private workshop with us.

Ready to Print Photogravure Plates

You supply the image as you like it on your display. Save it with an embedded profile. We produce the plate either to send to you for printing in your studio, or we can print it in ours!

Within the maximum plate area you can choose to have the plate trimmed to the image or include a plate margin (unprinted border around the image) as in the photo on the left which is a standard 3/8" margin. The image will cause an impression to be impressed into the paper. With a plate margin there to be a border of un-inked paper around the image surrounded by an impression into the paper.

Within the maximum plate area you can choose to have the plate trimmed to the image or include a plate margin (unprinted border around the image) as in the photo on the left which is a standard 3/8" margin. The image will cause an impression to be impressed into the paper. With a plate margin there to be a border of un-inked paper around the image surrounded by an impression into the paper.

Plate Pricing. There are two ways to work with us.

One is on your own and you take control of your imaging & cropping and use our inexpensive upload Shopify store which has lower costs in shipping by taking advantage of Shopify's shipping accounts. Here is a link to our Shopify store: https://shop.cone-studio.com/collections/photogravure-plates-ready-to-print You will find the pricing lower that when working with us directly because we are less involved in the process of originating the orders or adjusting images or questioning what is needed. You do all of that on our Shopify store with easy shipment options and very quick service because we process these orders as they are and when they come in.

The second way is to work with us directly, having email or phone conversations if needed, and transferring your image files to us or and asking for adjustments or tuning, etc. This has a different cost and these are the costs per plate. These are up to pricing and your image must fit on these plate sizes either cropped with in the plate size or including unprinted margins within the plate size. For example if you require a 11x11 inch image with 3/8" plate margins you will be charged for the 13x19 plate because your entire image is 11.75" x 11.75" with the plate margins.

Proofing and printing costs. Proofing is when we trial your plate using various inks or techniques according to your desired outcome. It is the most important aspect of printmaking. Think of it as the composing part of a symphony rather than the presentation of the symphony to a live audience. This is where the creativity lies. Where this was the longest part of our printmaking in the 1980s, 1990s, and 2000s the digital age as ushered in an era of expectations related to one's imaging experience rather than the printing experience and many of our customers do not proof. Rather they go directly to print. Many have no intention of us making more than one print from a plate. And others want to see their images inked in different color tones of pigment etching black or in actual color inks. Some want to see what the image looks like with no plate tone or with plate tone left on the plate. Others want to see their work on eastern washi paper against western paper choices or and on warm or bright papers, etc. Proofing costs the same as printing because it is printing.

First things first is the setup. We will take the paper you request and soak it briefly in water to begin softening the fibers and then we will drain and pack this in plastic sheeting overnight so that the moisture travels evenly through the paper formation leaving it damp but not wet. We will make fresh etching inks for your project using a scale so that we can duplicate it. After printing we will take the damp prints and place them in our flattener-dryer for a period of several days. From there they are reoved and either trimmed or torn to the size requested and slip sheeted. This setup cost is encountered each time we begin a proofing or a printing session for you. The costs range from $200 to $500 depending upon the size of the plates/papers and amount of work to be done. Proofing or printing plates 5x7 through 11x14 will cost $200 for your setup fee. Proofing or printing plates 11x17 through 16x20 will cost $300 for your setup fee. Proofing or printing plates 20x24 through 24x36 will cost $400 for your setup fee. Proofing or printing plates up to 30x40 will cost $500 for your setup fee.

These are the actual costs per proof or print.

On up to 11x15 paper

1-4 prints per each plate $115 each print

5-10 prints per each plate $95 each print

10+ prints per each plate $85 each print

On up to 15x22 paper

1-4 prints per each plate $165 each print

5-10 prints per each plate $150 each print

10+ prints per each plate $133 each print

On up to 22x30 paper

1-4 prints per each plate $275 each print

5-10 prints per each plate $260 each print

10+ prints per each plate $240 each print

On up to 30x44 paper

1-4 prints per each plate $500 each print

5-10 prints per each plate $402 each print

10+ prints per each plate $350 each print

If you come to Cone Editions Press to work with us,your costs are $450 per day and 40% off the above rates.